2024-10-04

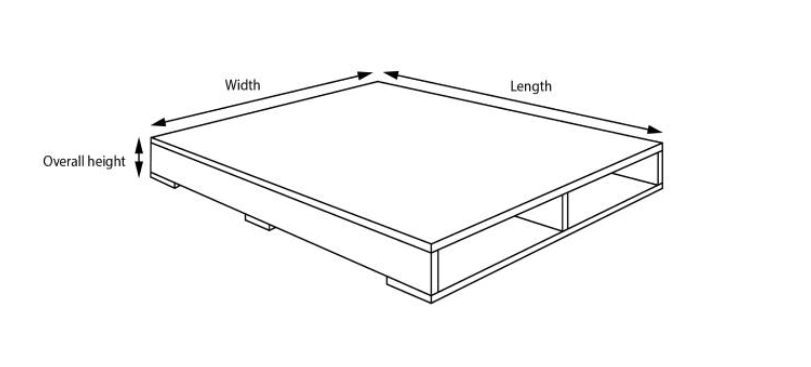

A standard pallet is a portable platform that serves as a base for cargo. Standard pallets are usually wooden but can also be plastic or metal. When you have large quantities of products, large equipment, or other goods that must be shipped as cargo, they must be palletized. To do this, you need to stack boxes or place the goods on an appropriately sized platform and then tie them down with safety straps or shrink wrap.

As different pallet sizes represent the economies and interests of different regions and countries, the International Organization for Standardization (IOS), in order to make a standard version of pallet sizes worldwide, approved six standard pallet sizes in 2003 by the ISO after a number of phased deliberations by the IOS/TC51 Technical Committee on pallet standardization, which is now widely used as the global standard pallet sizes. Here is the size of the IOS standard pallet.

| Dimensions mm (WxL) | Dimensions inches (WxL) | Region Most Used In |

|---|---|---|

| 1016 x 1219 | 40 x 48 | North America |

| 1000 x 1200 | 39.37 x 47.24 | Europe, Asia |

| 1165 x 1165 | 45.9 x 45.9 | Australia |

| 1067 x 1067 | 42.00 x 42.00 | North America, Asia |

| 1100 x 1100 | 43.30 x 43.30 | Asia |

| 800 x 1200 | 31.50 x 47.24 | Europe |

Pallet sizes in North America vary due to specific needs, industries, and materials used to load and unload cargo. That said, the most common size for plastic and wood pallets is 40 inches x 48 inches, which is the GMA (Grocery Manufacturers Association) approved pallet size. It is also one of the six pallet sizes specified by ISO. Here is the size of the North American standard pallet.

| Dimensions mm (WxL) | Dimensions inches (WxL) | Industry of use |

|---|---|---|

| 1016 x 1219 | 40 x 48 | Grocery, many others |

| 1067 x 1067 | 42 x 42 | Paint |

| 1219 x 1219 | 48 x 48 | Drums |

| 1219 x 1016 | 48 x 40 | Military, Cement |

| 1016 x 1067 | 40 x 42 | Chemical, Beverage |

| 1016 x 1016 | 40 x 40 | Daily |

| 1219 x 1143 | 48 x 45 | Automotive |

| 1118 x 1118 | 44 x 44 | Drums, Chemical |

| 914 x 914 | 36 x 36 | Beverage |

| 1219 x 914 | 48 x 36 | Beverage, Shingles, Packaged Paper |

| 889 x 1156 | 35 x 45.5 | Military 1/2 IOS container, fits 36" standard doors |

| 1219 x 508 | 48 x 20 | Retail |

As the material handling needs of European countries have developed, many different sizes of pallets have appeared. In the last few years, European pallets have been standardized to a certain extent, and the European standard pallet we now use more widely is called EUR Pallets. It measures 1200mm x 800mm (31.50“ x 47.24”) and is one of the six pallet sizes recognized by the IOS. Here is the size of the European standard pallet.

| Dimensions mm (WxL) | Dimensions inches (WxL | ISO Pallet Alternative |

|---|---|---|

| 800 x 1200 | 31.50 x 47.24 | IOS, same size as EUR |

| 1200 x 1000 | 47.24 x 39.37 | ISO2 |

| 1000 x 1200 | 39.37 x 47.24 | / |

| 800 x 600 | 31.50 x 23.62 | ISO0, half the size of EUR |

| 600 x 400 | 23.62 x 15.75 | Quarter the size of EUR |

| 00 x 300 | 15.75 x 11.81 | One-eighth the size of EUR |

There are a number of standard sizes of Asian pallets. Both sizes below are included in the list of ISO standards. 1200mm x 1000mm (39.37″ x 47.24″) is a size that fits well into the European and American systems, so this size of pallet is more suitable for exporting from Asia to Europe and the USA. Here is the size of the Asian standard pallet.

| Dimensions mm (WxL) | imensions inches (WxL) | Region Most Used In |

|---|---|---|

| 1100 x 1100 | 43.30 x 43.30 | Europe, USA |

| 1200 x 1000 | 39.37 x 47.24 | Europe, USA |

Standard pallet sizes in Australia are common in that country but not in other parts of the world. Standard pallets in Australia are made from hardwood or softwood, which are durable materials that can carry very heavy loads. They are designed to fit perfectly into and with the RACE containers of Australian railroads. Here is the size of the Australian standard pallet.

| Dimensions mm (WxL) | Dimensions inches (WxL) | Industry of use |

|---|---|---|

| 1165 x 1165 | 45.90 x 45.90 | Grocery, Others |

Consideration of cargo is critical when using pallets to transport goods. Each type of pallet is designed to handle different weight loads. Some pallets may require special handling, so it's best to contact your agent and ask them which type they prefer or if they have the equipment to handle it.

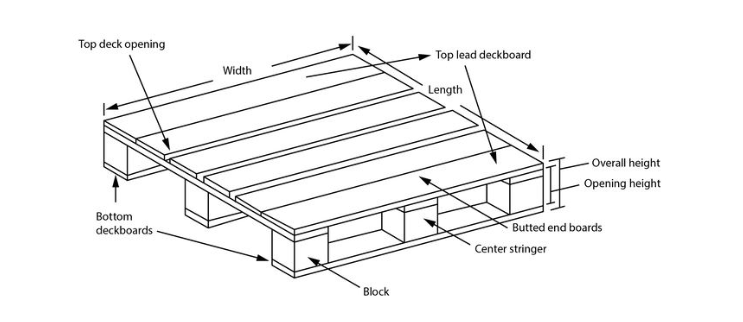

Block pallets are designed with blocks (typically made of metal, plastic, or wood) in each of the four corners, one block in each corner, one block in the center of each side, and one block in the center of the platform, the space between the blocks is passable by a forklift this means that the forklift can insert the fork tines and lift the platform from either side. Block pallets are a popular choice, and they appear to be very efficient in material handling. You can arrange them vertically or horizontally in warehouses or transportation trucks because they simplify material handling logistics. They are often used in industries that require easy and flexible handling of products, such as warehouses, shipping, and logistics. Block pallets are also known for being stronger and more durable.

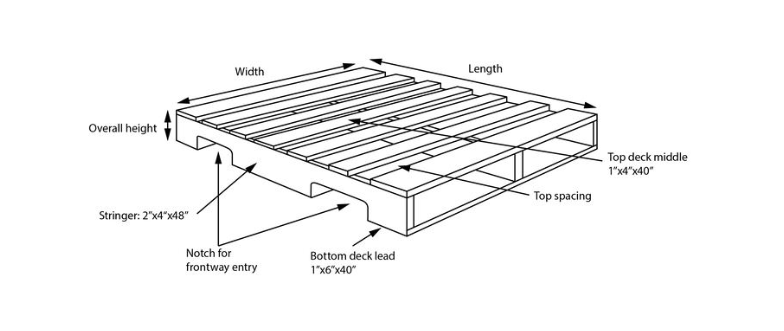

Stringer pallets are designed with a structure consisting primarily of two or more longitudinal directions sandwiched between the upper and lower decks, with the two longitudinal beams enclosing the two opposing sides and the other plank passing through the center for added support. This kind of pallet brings greater stability and load-carrying capacity. They are often referred to as two-way pallets because forklifts and pallet trucks can only access them from both sides. Usually made of metal or plastic, pallets are durable and suitable for multiple reuse, especially for automated warehouse systems or high floors. Compared to regular flat pallets, stringer pallets are able to spread out the weight and are suitable for carrying heavier or larger loads. In addition, the open design of the stringer pallet makes it easier for forklifts to pick up and move the pallet, which improves work efficiency.

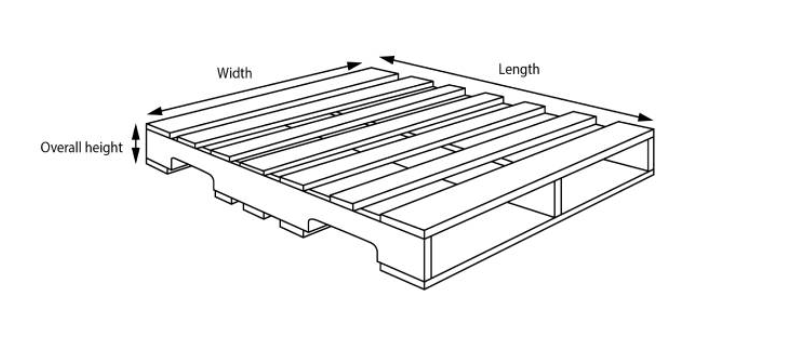

A double-face pallet is a design that has a double-sided structure with a top plate and a bottom plate. This design means that both sides of the pallet can be used for loading. The bottom plate makes the platform stronger and allows for more weight to be distributed evenly. Some double-face pallets are reversible, and on reversible pallets, both boards can be used as either the top or bottom board. Non-turnable pallets usually have a stronger top plate with more side plates to support the load. This design provides greater stability and flexibility for use in a variety of warehousing and logistics environments. Double-face pallets can be categorized into wood, plastic, and metal types, and their main advantage is that they are strong and durable, can carry heavier loads, and are capable of high strength and multiple turnovers during use. For example, factory production lines, automated warehouses, and long-distance transportation. In addition, double-face pallets are more stable and effective when stacking. However, because both sides are designed as carrying surfaces, they cannot be inserted into the bottom using a standard forklift like single-sided pallets and require special handling equipment.

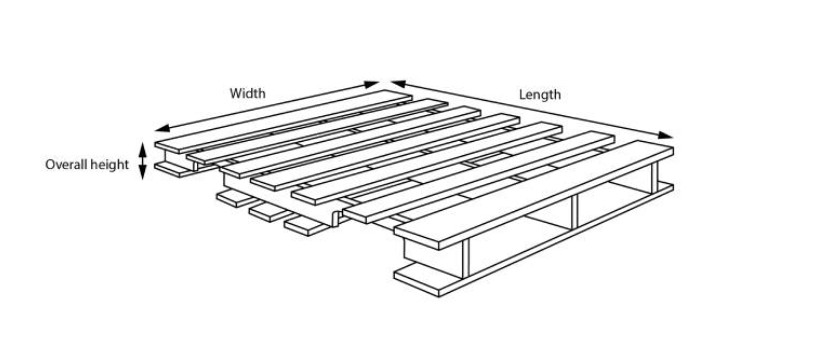

A double-wing Pallet is a pallet with a double-wing construction featuring a platform with top and bottom decks that extend beyond the longitudinal beam plates. Since the two decks overhang beyond the block or longitudinal beam, they look like wings. Both sides of the pallet extend out of the joists, thus providing additional support and stability. The design of this type of pallet allows for better distribution of pressure when handling goods and is suitable for applications requiring greater load-carrying capacity. Double-wing pallets are commonly used to transport heavy loads, especially in forklift and stacking operations, to increase the safety and handling efficiency of the load.

Solid deck pallets are generally pallets made of plywood with a deck that is a solid, one-piece board with no gaps or holes. Using a single solid board for the deck, these designs eliminate many nooks and crannies, making them easier to clean. You will often see plastic solid deck pallets used for food processing and shipping. There are also solid deck pallets made of wood, which may be more aesthetically pleasing and are a good choice for displaying products or delivering items to customers. They are also good for packing and shipping smaller items because they won't slip through the cracks. Solid deck pallets are durable and are generally used for high volume and heavy duty.

The use of pallets to transport goods can reduce the number of loose goods and reduce the chance of loss of goods (after all, the chance of losing a pallet is much lower than the chance of losing a small box of goods).

After the pallet, the goods as a whole are more solid, and you do not have to worry about the goods being deformed. The use of pallets will make the transportation process more efficient and safer.

The surface of the pallet is flat and can be fixed, and stacked goods, in the process of transportation and handling, play a role in protecting the safety of goods. With slots for forklifts or pallet trucks underneath the pallet, this shape makes loading and unloading easier and faster.

The standard size of the pallet allows carriers to maximize stacking to save storage space. Using pallets ensures that carriers handle your shipments correctly and that items are not easily lost in transit. Some shipments arrive at their destination with a per-box delivery charge, and if your shipment is a lot of small boxes, palletizing these small boxes can reduce your shipping costs.

Fragile goods such as ceramics, glass products, home appliances, etc. The use of pallets can reduce the risk of collision and breakage.

Mechanical equipment, metal products, wood and other heavy goods need pallets to facilitate handling and loading and unloading, and to avoid damage to the floor or equipment.

Small goods can be transported centrally on pallets to prevent scattering and improve loading and unloading speed.

Such as paints, cleaners, chemicals, etc. Pallets can provide firm support and reduce the risk of leakage or tipping.

Such as barrels of oil, liquid food, etc. The use of pallets can help ensure that these containers are placed in a stable manner to prevent tilting or leakage.

For electronic products, pharmaceuticals, and other high-value goods, the pallet provides additional protection to reduce the possibility of damage or loss during transportation.

Such as paper products, textiles, wood and other goods that are susceptible to moisture, the pallet separates the goods from the ground and prevents moisture or water damage. Transportation of these goods on pallets ensures safety and efficiency and reduces the potential for damage during handling.

How many standard pallets a truck can carry is something that many people are curious about. The amount of pallets a truck can carry depends on the size of the pallet, the type of truck, and how it is loaded. Let's use American Standard pallets (1200mm x 1000mm) and European Standard pallets (1200mm x 800mm) as examples. Below is an estimate of the pallet loading capacity for two common truck types:

Internal dimensions are approximately 12.03m x 2.35m x 2.39m.

Internal dimensions are approximately 5.9m x 2.35m x 2.39m.

When shipping pallets in order to reduce the risk of damage during transportation and incur more transportation costs. Here are a few effective ways to do this.

Choose different pallets according to different cargo sizes and materials. Choose pallets of appropriate size and strength to support the weight of the goods and use pallets with additional support beams or reinforcements to increase stability.

Distribute the weight evenly across the pallet, placing heavier fragile items at the bottom and lighter items at the top. This helps maintain balance and stability during handling and transportation.

Choose an experienced and reputable carrier. JIKEship has many years of very rich experience in pallet transportation and is your right hand in international goods transportation.

Transporting goods on pallets becomes very easy with our guidance. If you want to know more aboutstandard pallet size and different kinds of pallets or shipping goods internationally, please feel free to contact us. JIKEship is at your service 24/7.

| Contact Jikeship for freight services from China |

| Whatsapp - Online Customer Service |

Here, we will show everything about shipping from China to the USA, including the latest container shipping costs via different ports, shipping times, and more.

2024-08-03

We use third-party cookies in order to personalise your experience.

Read our cookie policy